0

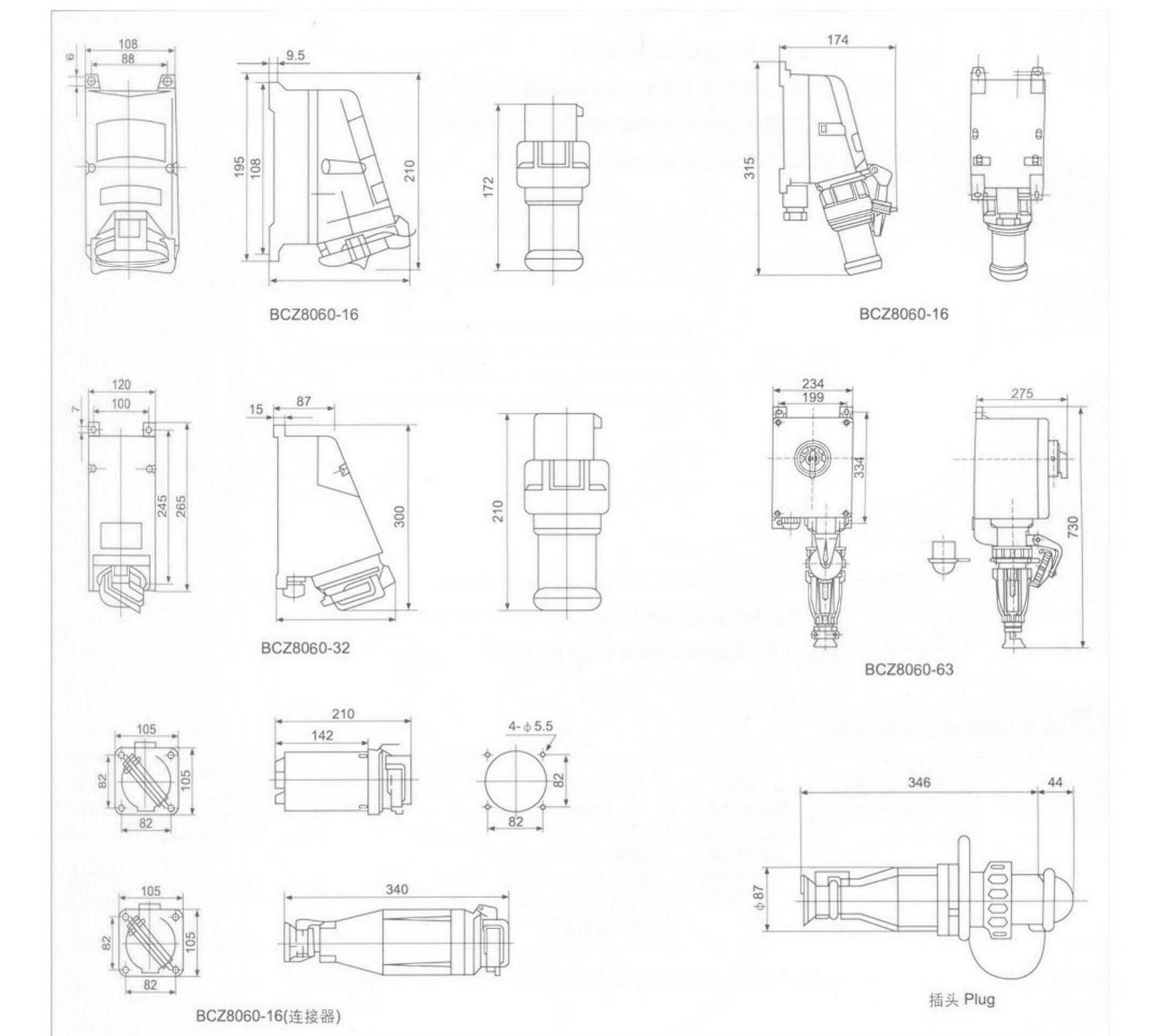

0| Models | AC8060-16A | AC8060-32A | AC8060-63A |

| Rated Current [A] | 16 | 32 | 63 |

| The cable for plug | Φ3mm-Φ14mm | Φ11mm-Φ18mm | Φ17mm-Φ28mm |

| Inlet threads | G 3/4" | G 1" | G 1 1/2" |

| Rated Voltage | 220/380VAC | ||

| Nos. of pole | 1P+N+PE, 3P+N+PE,4P+N+PE,5P+N+PE | ||

| Ex rate | Ex d e IIC T4 Gb, Ex tD A21 IP65 T80℃ | ||

| Function | Electrical Outlet Connection | ||

| Degree of protection | IP65 | ||

| Application | Zone 1&2 Zone 21&22 | ||

| Note | linker used for connecting distance-cable, linker current is only limited to 16A. | ||

| Operating Temperature | -5℃~+50℃ | ||

1. The shell of explosion-proof plugs is made of glass fiber reinforced unsaturated polyester resin pressed or welded with high-quality stainless steel. Explosion-proof plug's corrosion-resistant, antistatic, impact-resistant and has good thermal stability.

2. Stainless steel exposed fasteners, high corrosion resistance.

3. The enclosure is Safety-increasing type with flameproof switch inside.

4. Pluas are connected to electrical equipment.

5. The socket is equipped with reliable mechanical interlocking device, that is, the switch can be closed only after the pluą isinserted into the socket, and the plug can be pulled out after the switch is disconnected.

6. The socket is equipped with a protective cover. After the plua is pulled out, the socket is covered with a protective cover toprevent sundries from.entering

7.Steel pipe or cable wiring is acceptable.

1. A wide range of hazardous areas where ignitable vapors, dust, moisture and corrosive elements are present;

2. Areas requiring frequent on-and-off of lights or power cycling- no warm up time required;

3. Areas with high energy costs

4. Typical applications include:

Oil and gas industries

Chemical, petrochemical

Pharmaceutical industries

Pulp and Paper

Waste and sewage treatment

glass fiber reinforced unsaturated polyester resin pressed or welded with high-quality stainless steel