0

0| Model | MXEL 8198-2 |

| Tube Power | 1*18W, 2*18W, 3*18W |

| EX-proof Mark | Ex D IIC Gb T6 |

| Cable Entry | G3/4" |

| Input Voltage (V) | 2200VAC, 50-60Hz |

| Light Source | LED |

| CRI (Ra>) | 70~80 |

| Lamp Luminous Efficiency | 100lm/w |

| Working Temperature (℃) | -25℃ - 45℃ |

| Delivery Time | 5-7days |

| Certifications | ATEX, ROHS, CE, CCC, IEC, CNEX, ISO |

| Material | Steel Plate, Stainless Steel Optional |

1. Shell protection shell lamp

The transparent body is made of reinforced carbonate material, which has the characteristics of high strength, strong impact resistance, high temperature resistance, cold resistance, etc.

2. Long life, full light decay

MXEL 8198-2 ATEX explosion proof fluorescent light has more precise light control, high light efficiency, more in line with the actual lighting environment, long switching times and service life, high lumen maintenance rate, slow light decay, improved beam distribution, high color rendering, energy saving and environmental protection.

3. Unique circuit design

The built-in ballast is a special explosion-proof electronic ballast, which has short-circuit and open-circuit protection functions. MXEL 8198-2 ATEX explosion proof fluorescent light is equipped with a preventive circuit for the aging effect and leakage of the lamp. MXEL 8198-2 ATEX explosion proof fluorescent light adopts a specially designed sealing strip, double sealing, and more excellent protection performance.

4. Simple maintenance and easy installation

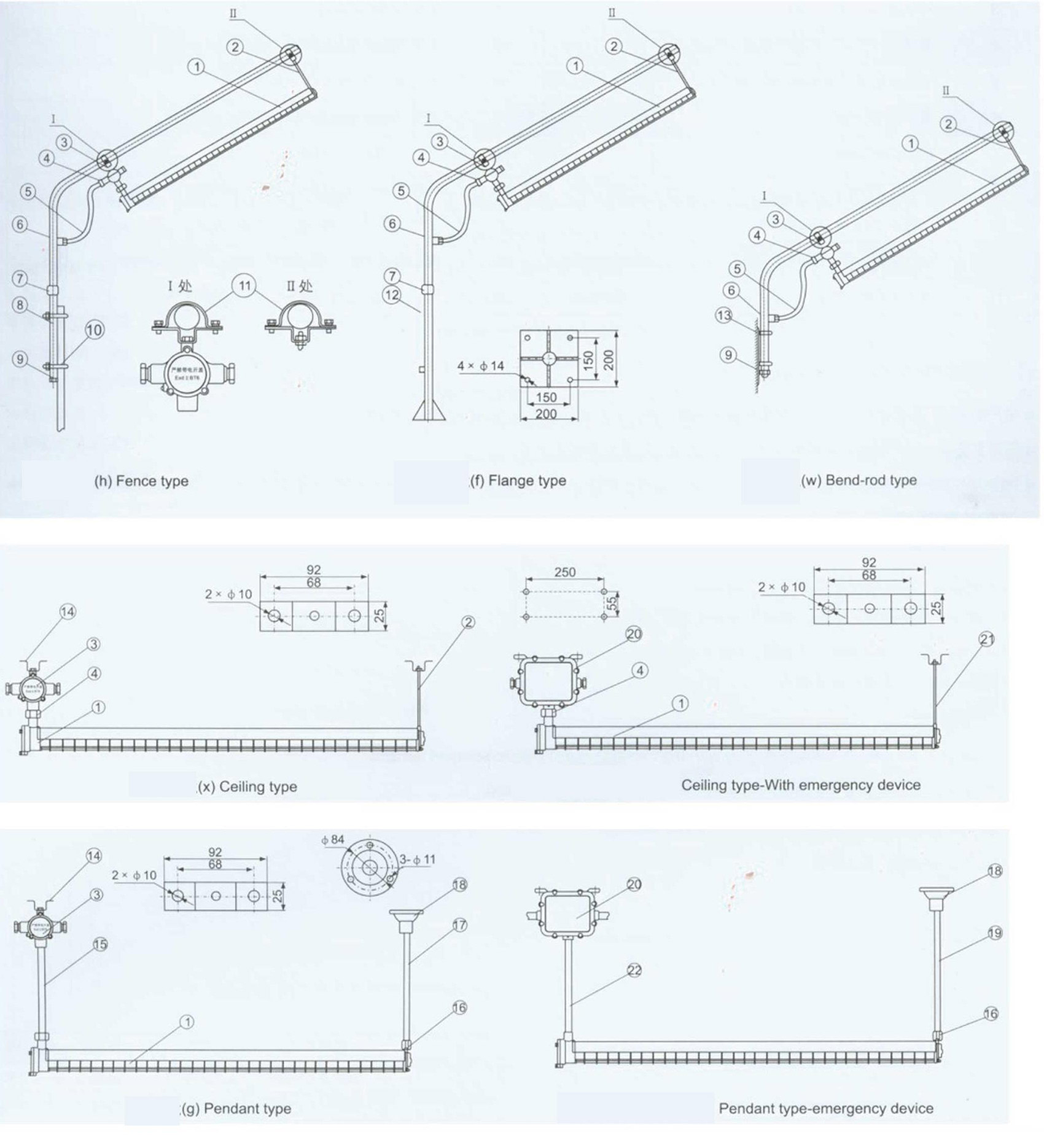

The maintenance is simple. When opening and closing, you only need to insert a screwdriver into the small opening of the buckle. A variety of installation methods, can be embedded and ceiling installation.

| Rated current | AC 220V 50 Hz or as per requirement |

| Ex marks | Ex d IICT6 |

| Degree of protection | IP66 |

| Corrosion resistance | WF1. WF2 |

| Tube | T8 bin pin fluprescent |

| T5 Bi-pin fluorescent | |

| LED Lihgt | |

| Cable glands | G3/4 or as per requirements |

| For cable OD | 9mm to 14 mm |

| Battery charging time | Less than 24 hours |

| Emergency starting time | Less than 0.3 |

| Emergency lighting time | More than 90 min |

| Branch | Explosion Hazard | Branch | Explosion Hazard |

| Chemical Industry | Flammable Gases/Liquids/Solids | Paint-spraying | Overspray in Spray-paint Bays |

| Solvent Vapor Emissions | |||

| Landfills | Flammable Landfill Gases | Agriculture | Bio-gas Production Plants |

| Uncontrolled Gas Emissions | |||

| Civil Engineering | Flammable Gas from poor ventillation sources | Bio-gas Located on Farms | |

| Power Generation | Lump Coal Dust | Metal-work | Explosive Metal Dust |

| Spark-ignitable Metal Dust | |||

| Waste Disposal | Waste-water Treatment Gasses | Food/Beverage | Overspray in Spray-paint Bays |

| Solvent Vapor Emissions | |||

| Gas Suppliers | Natural Gas Leagage | Pharmaceutical | Alcohol Solvents |

| Materials explosive when mixed | |||

| Natural Gas Emissions | |||

| Woodworking Industry | Saw Dust Fine Wood Chips | Refinery | Hydorocarbons close to their flash-points Oil Processing Plants |